Hexagon Metrology serves the high precision measurement and inspection needs of Worldwide manufacturers with its extensive line of metrology hardware, software, accessories, and customer services. The addition of PolyWorks for new equipment from Brown & Sharpe, DEA, ROMER and Leica Geosystems, plus existing equipment upgrades represents a great benefit for our customers who wish to collect and analyze large amounts of free-form data.” “ PolyWorks has significant acceptance at many of our major OEM customers, most of which already own multiple Hexagon Metrology technologies such as portable and stationary CMMs.

Bill Gruber, President and CEO of Hexagon Metrology, Inc. “ We are very pleased to be able to introduce this range of non-contact scanning packages to the market” said Mr. Combining Hexagon’s strong position in the 3D measurement technologies with our PolyWorks inspection and reverse engineering solution will enable both organizations to increase even further their respective market share in North America,” he continued. “ In addition to the demand for new hardware systems, we have observed that retro-fitting of existing CMMs with laser scanners is also a key growing market. “ This agreement represents a major business opportunity to partner with a world-leading supplier of stationary & portable CMMs and 3D laser scanners,” said Marc Soucy, President of InnovMetric Software Inc.

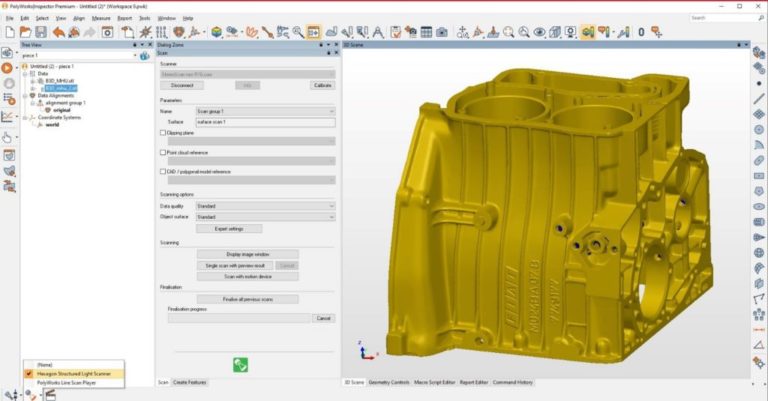

Manufacturers in automotive, aerospace, heavy equipment, and general engineering and manufacturing industries can benefit from this solution. If you are already using our solutions and you would like to discuss some additional features, feel free to reach out to us, and we will do our best to improve your experience.The hardware and software combination allows manufacturers to quickly digitize parts and use the resulting point cloud data to inspect, reverse-engineer and perform other computer-aided engineering tasks such as finite element analysis, rapid prototyping, and computational fluid dynamics.

👉🏻 Our solutions can be tailored to our clients’ needs, and GE Appliances’ were fully met! Our solution has provided GE Appliances with a collaborative, user-friendly interface that makes the data available for the right people, at the right time ✅ ▶ Watch the video to find out how PolyWorks has boosted GE’s digital transformation by facilitating the aggregation of large volumes of 3D metrology data on a single software platform, all while using different measuring devices. Thank you, GE Appliances, a Haier company, for this positive feedback on our solutions PolyWorks|Inspector and PolyWorks|DataLoop! We are very proud to contribute to your growth, innovation, and evolution, and to have made such a difference in your metrology processes.

0 kommentar(er)

0 kommentar(er)